Thermal Stabilization of Vaccines

Making Vaccines Easier to Distribute through Thermal Stabilization

ThermoVax® is a proprietary method of preparing vaccines composed of protein and adjuvant such that they can be lyophilized (freeze-dried) while maintaining optimal potency. Once lyophilized, the vaccines are generally stable even at elevated temperatures (e.g., 40°C or 104°F) for extended periods of time. ThermoVax® has the potential to eliminate the need for cold-chain production, transportation and storage – relieving the health care system of the high costs of producing and maintaining vaccines under refrigerated or frozen conditions.

What is Thermal Stabilization?

Many vaccines are unstable at room temperature and lose their efficacy over time. The higher the temperature, the faster this degradation occurs. Therefore most vaccines are produced, transported and stored under refrigerated or frozen conditions, adding significantly to their cost and to waste due to temperature control problems. Thermal stabilization is the process of formulating a product to withstand higher temperatures without degradation.

The World Health Organization (WHO) reports that 50% of all vaccines around the world are wasted due to thermostability issues. Elimination of the cold chain would facilitate the use of these vaccines in the lesser developed parts of the world. From the biodefense perspective, ThermoVax® has the potential to facilitate easier storage and distribution of strategic national stockpile vaccines in emergency settings. Subsequent savings from the elimination of cold chain costs would also increase the profitability of vaccine products.

Learn more about thermal stabilization

How is thermal stabilization achieved?

Protein degradation generally occurs due to the presence of water, enhancing chemical reactions which degrade the protein. Lyophilization (also known as freeze drying) is a well-known method to remove the water from a protein mixture without degrading the protein. Unfortunately, freeze drying vaccines with adjuvants such as aluminum and nano-emulsions have been known to enhance particulate formation, making the product less efficacious.

The ThermoVax® process uses additional components to aid in the suspension of the adjuvant–protein mixture preventing particulate formation and enabling adjuvanted vaccines to be lyophilized.

More details on thermal stabilization can be found in our Reference Literature.

How effective is thermal stabilization?

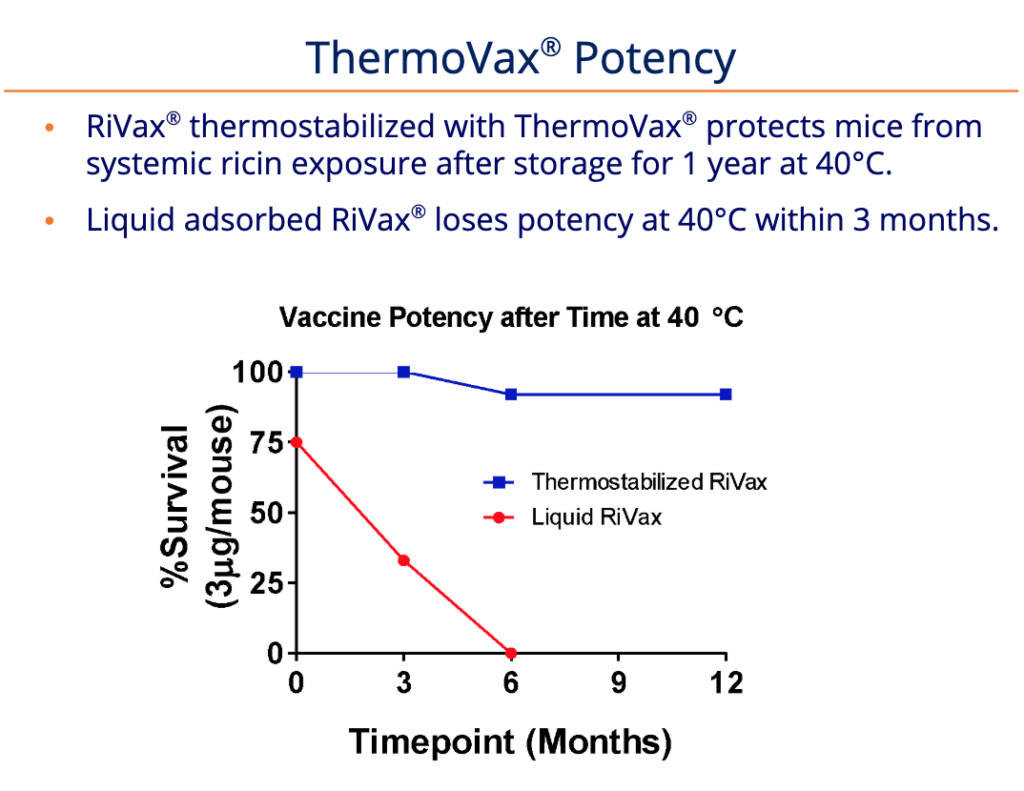

The ThermoVax® technology has been incorporated into Soligenix’s ricin toxin vaccine program (RiVax®). The RiVax® when formulated as a liquid is very unstable, while the thermostabilized formulation retains potency even after storage for 12 months at 40°C (104°F).

What Vaccines can be ThermoVax® Stabilized?

In principle, any aluminum or nano-emulsion adjuvanted vaccine may be stabilized by the ThermoVax® process.

To date, a number of aluminum-adjuvanted protein subunit vaccines have been successfully stabilized, including a ricin toxin vaccine, anthrax vaccine, an HPV vaccine and an Ebola vaccine.

Stabilization of CoVaccine-HT vaccines candidates for filoviruses have also been demonstrated. Please contact us for details.

Interested in exploring whether ThermoVax® thermal stabilization will work for a different vaccine?

Soligenix is interested in collaborating.